Business How-To's

2023 Best 3D Printers For Your Business Or Print Farm Buying Guide

Do NOT buy another printer until you read this…

06 August 2023

In this guide:

-

The single most important factor when choosing a printer.

Hint; it’s not print speed or quality. - Why you shouldn’t buy based on price, and the benefits of a trusted name.

- How to choose between a Prusa MK4 or Bamboo X1 Carbon for example for your business.

- Which SLA Resin printers are the best workhorses and why.

Getting the right 3D printers for your business can be a minefield, with hundreds of different machines available. Each model of 3D printer requires you to invest hours “learning the ropes” even before we consider the output factors we need and the available investment we have.

So, this isn’t something you can blindly jump into, because getting it wrong can lead to countless hours of frustration and lost profits.

In this article I’m going to help you cut through the noise and get down to the most important factors for your business, because your business is likely different in some way.

That means I won’t be quoting every stat and figure on printers - I’ll just be sharing with you what is actually important and why when making a purchasing decision - for either a small or home business.

This article will be useful to many looking to buy printers for their business, but primarily we’re talking small businesses here anywhere from a few thousand dollars a month on their first hobby printer, all the way to those doing less than $1 million annually selling their 3D prints.

People make a lot of mistakes choosing printers to start a business. I’m going to help you avoid those. For example, I have a client who had a print farm with 47 Creality Ender 3’s when I started working with him - except only about half were ever working, the others were on his constant “to-fix” list.

Don’t get me wrong, an Ender 3 is a great ~$300 machine to learn on as a hobbyist, but it’s a terrible printer for business.

Likewise, don’t buy loads of different printers. Each one takes a learning curve and that time could be better spent growing your business.

If you expect to build a print farm as you scale your business, they should all be the same unless you need to switch type because the need arises. I.e from FDM to SLA (Resin) for example.

Also worth mentioning, I don’t have any affiliation with any printer manufacturers (any more) so I can give you entirely unbiased advice. Which is more than can be said for many other “buyer’s guides” out there.

I’ll also make some specific printer suggestions which I’ll periodically update in the future as required - so you can keep your business plan current. It’s likely my suggestions won’t be “popular” but my findings are based on experience and the metrics that matter.

But before I share what specific printers you might consider, you need to understand why you need a certain printer over others. So many miss this vital point, and rush in to buying a printer or 10 that seem like a good idea at the time, but then realise that they were unreliable, or couldn’t produce the parts that their customers actually wanted.

So I’m going to assume that you know full well what product or items you’re going to be printing beyond this point - you’re clear what kind of business model you’re operating. You know what visual quality the customer is expecting, you know the size, you know what the part has to do (i.e strength, durability or weight criteria).

If you don’t know these things; if you don’t already know what you’re making - I’m afraid you will not be able to accurately decide what printers you need. It’d be like calling up a car dealership and saying you want them to deliver you a new car today, but you’ve not told them what type of car you need.

So they have no idea how many seats it should have, how fast it should be, trim levels etc. etc.

...you get the point.

So if you are just starting out and deciding what you should be making to sell your prints, I invite you to check out my guide to begin with, where I help break down what you need to look for when trying to figure out what 3D printed products you could sell. Click the button below for your free copy.

Because as hobbyists we might decide on what printer to buy first, and then decide what to print with it. But as business owners we decide on what we’re gonna print on it first, then decide what machine is going to be best for the job.

So let’s dive in…

Reliability is the single greatest priority for you when choosing a 3D printer for as a small business business use. If it's just you or a small team running the show, you can’t afford to have surprise down-time.

I can’t stress this enough - building a print farm with general OK-for-hobbyist printers from China (sorry, China) is going to lock you up in breakdowns, extra maintenance and eventually; increased anxiety.

You might think replacing a part for a machine is just half an hour of your time, perhaps. Or having to re-level the bed every few weeks, and that’s worth a $500 - $700 saving per machine?

But the reality is that it’s going to happen when you’re at your busiest, you’ll have so many orders and won’t have the time to fix it…

So you put it off for a few days or weeks, and before long you’ve had restricted production capacity for all that time and then the other printers might have similar faults and you have mounting orders and no time to fix those printers.

That’s a hobbyist mindset, and it will keep you stuck.

So stay away from those “hobby” printers, like Creality, Anycubic etc.

-

Note:

A key exception to this is if you’re going to use automation. A popular printer automation tool like 3DQue will actually typically increase your printer’s reliability thanks to the fact that nothing changes each time and humans aren’t touching it.

-

-

Turns out machines running machines get much higher reliability for same repetitive tasks than humans can, who knew?

The next most important factor for a 3D printer, is the speed. Why? Because a single printer that is 3 times faster than another, is the same as having 3 printers.

So speed is better than price. A lot better. Let me explain;

Take the Prusa MK3s, it’s now reduced to $900. The new Prusa MK4 is $1100, so the price is $200 more.

Which is cheaper?

The new MK4 is over 3 times cheaper than the MK3s.

That’s because, in draft mode it’s 4 times faster. So having a MK4 is like having 4 x MK3S’s, which means comparatively for business output; using MK4 tech is like buying MK3s for $1100 / 4 = $275 each.

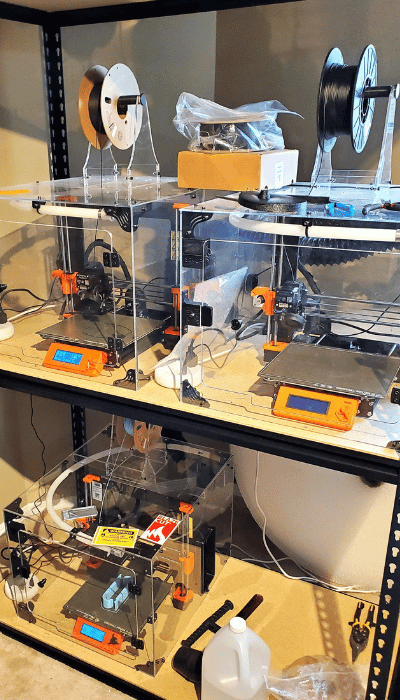

Photo: Jim Fehr Printer Setup

So having a MK4 is like having 4 x MK3S’s, which means comparatively for business output; using MK4 tech is like buying MK3s for $1100 / 4 = $275 each.

That’s why in real terms the Prusa MK4 is always the better choice. One of my past clients built his business to $16,000 per month selling his 3D prints and he only used 3 x MK3s’.

He could’ve now used just one MK4 to do the same volume. It might be crazy to think you could do $16,000 per month using just one $1100 printer, but we have many clients doing similar.

While other factors, such as print quality and build volume do come into play, this for the majority of business owners, is a much lower concern - essentially because most popular printers on the market now, that are recent releases (within the last 3 years) have respectable quality settings.

Like the car analogy above, all new cars have very similar safety ratings, so it tends not to be your primary concern when looking for one (though, still worth checking).

Most of the sorts of products and parts you’ll be printing for customers, if you’re making 3D prints to sell, will not need to be “injection moulded” levels of surface quality. This may surprise you, but certainly, for functional prints, the use of the part is the primary concern.

For small detailed and intricate parts, your best option by far is an SLA or DLP Resin-based printer. Not only are these machines very high quality output, but for small parts, they’re insanely fast.

That’s because a part that’s about 1” x 1” x 2” tall might take a few hours to print. But if you wanted to print 25 of them on the bed all at once, it would take the same amount of time.

So, if you know the size and quantity you’ll likely be needing to print, you’ll have a much better idea on which printers you’ll want to invest in.

One of the cons to MSLA, SLA or DLP resin printers is that the strength of the finished part compared with FDM (filament) based machines is typically much lower. They’re also a little more messy, and the resin if you get any on your skin is detrimental to your health, so you want to make sure you’re taking the necessary precautions.

So your price per print is going to be an important factor when choosing a printer, and it ties in closely with the print area of the bed of the printer and of course the size of your model.

Total print volume can be factor, but you’re unlikely to use the full amount of build volume offered by a printer (which is the bed size, times the available height) - far more important for printing most products is just the bed area.

That’s because it’s rare that you’ll print very large or tall objects profitably with a 3D printer. This takes a lot of time, so eats into your profit margins and can increase failure chances, which we always want to avoid.

So it’s not that you can’t make money printing medium or large sized stuff, it’s just much harder. We always advise our clients to create products that have at least a 10x profit margin (meaning if a print costs $2 all-in, you’re selling it for at least $20-$25), as this is a critical figure for scaling any 3D printing business.

To illustrate Price Per Print, we could compare two of the best SLA 3D printers for business:

Elegoo Mars 3 MSLA

At the low end of the market we have this ridiculously capable machine. It’s high quality and actually built to last (yes, it did come from China - my comment above is the “rule”, so there’s always exceptions).

It’s expected that the light output will only degrade around 5% after about 6000 hours of use, so it’s a solid looking workhorse.

It has a bed area of around 128cm² which is smaller than the Form 3 below.

Worth noting that you also really need to purchase curing and washing bundles to keep things efficient and clean, though this is the same for all resin printing.

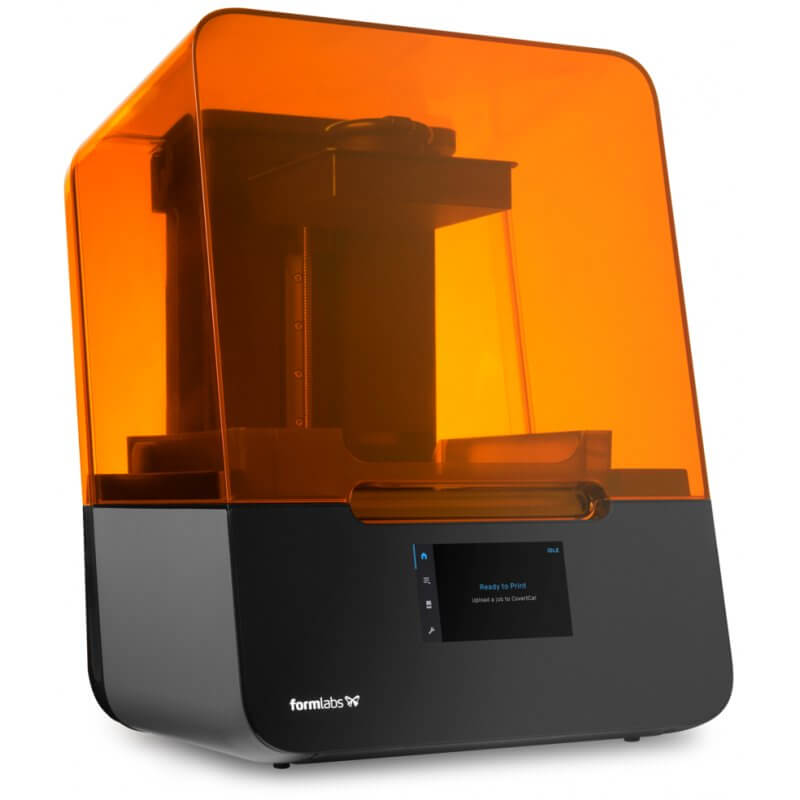

FormLabs Form 3

Easily one of the best SLA printers out there, the Form 3 is the real deal. It’s marginally better on paper than the Mars 3, but it’s over 11 times higher priced.

Note I didn’t say, more expensive though - because with a bed size of 210cm² it’s approximately 64% larger. Which for business purposes cuts down the cost in real terms lowers it to *just* 7 times more.

It is also longer lasting, and even more reliable - it will just work time and time again, so you have additional work hours saved, there.

However, it also has the option for Form Auto, which is an automation add-on which will pretty much turn your Form printer into an automated factory that only needs the resin cartridges replacing and the parts emptying from the bins periodically.

But when on a budget, the Mars 3 setup is impressive.

Prusa MK4 vs. Bamboo Labs X1 Carbon

The MK4 was in a nutshell, viewed as a little bit “too little, too late” by many on first appearances. To say Prusa is well known in the 3D space is a bit of an understatement, but it seems like they were dragging their feet working on this one (took them 5 years) and even when they did release it seemed a bit rushed, as they realised they had to compete with Bamboo Labs’ incredible X1 Carbon.

The X1C easily beats the Prusa MK4 on paper, it’s print area is nearly 25% larger, it’s got more features and well regarded as a brilliant machine.

However, for most business applications we’re finding the MK4 has just got what makes sense: better/faster customer support, and a more tried and tested reliability record.

Which ultimately, while the Bamboo X1 Carbon might save you some time with its larger bed and useful features, the less glamorous Prusa MKIV (4) will likely be a wiser long-term play.

After-all, Prusa themselves use hundreds of these in their massive print farm, going 24/7 - so as you’d expect most of the reliability kinks should be ironed out for a newish printer.

There are other machines, but few compare with the two above - many just don’t make sense unless you need a much larger print volume.

I wanted to include the following options just so you had a full stack of the tools you’d likely use for business.

If you’re looking for parts that are the strongest you can get without going down the Desktop Metal route, you’re going to want to look at the Markforged range.

That’s because these guys are the only ones to offer an option of “Continuous Fibre” for Carbon Fibre or Fibreglass prints. Other filaments might have small pieces of fibre in the filament, which doesn’t hugely affect strength - whereas the continuous fibre creates a part that is as they claim “as strong as aluminium”.

However, due to the high material costs (they have a monopoly over their Continuous Fibre filaments) it’s tricky to make these types of products profitable unless you’re charging sufficient prices.

The Onyx Pro™ is the cheapest option at $9600, giving the Fibreglass option. For the Mark Two™ you’re going to get real CarbonFibres strength for around $17,500.

There’s a reason these machines are typically more used for bespoke specialist end-use parts for businesses with internal R&D departments, as opposed to batch printing end-use direct to market products from small businesses.

Don’t buy your next printer until you need one. Save the money or invest it in ways to grow your business.

Unless you’ve having a 3 month waiting list on a printer, nearly all businesses can be started with just one printer, and you can scale up from there. I speak with businesses all the time that already have 5 or 20 printers, and they have excess production capacity. That’s a fair bit of money tied up in machines you might not need, yet.

Far better to start with one (the right one you need) and then buy more of the same with the profits from the first machine. Remember; with the right numbers for your products, you should be able to easily produce $1000-2000 per month of net profit, per machine.

Many of our clients have even exceed $5000 net profit per month, per printer, which is possible but not typical.

With this knowledge and most importantly, a longer-term mindset so you’re empowered on how to make the right choice for your business, you’ll be able to make much higher quality decisions that are hopefully more based on the facts for your situation, rather than what you wanted to get or what you heard someone else recommend.

Comment below to share your experiences with either unreliable printers, or something that’s been a surprisingly trusty workhorse for your business!

If you’re looking for a more technical buying guide that goes a lot deeper into all the factors you might consider when purchasing a 3D printer for business or personal use, check out our Industry Leading Unbiased Buyers Guide here.

Share this post on:

Ed Tyson

Having successfully scaled multiple ecommerce businesses on a variety of platforms & been featured in online 3D printing publications, he's now looking to help you increase sales of your 3D printed products and identify higher-margin product opportunities to build your wealth.

OTHER POSTS

-

29 August 2023

-

18 July 2023

CATEGORIES

CONNECT WITH ME

Ed Tyson

SUBSCRIBE

Tell us where to notify you when we post:

ABOUT US

The #1 Authority on helping 3D printing businesses scale by finding more profitable, easily 3D printable products, that customers want to buy.

If you’re looking to make more money with 3D printers, let us show you how hundreds of businesses have already transitioned away from feeling overworked and underpaid, to enjoying a solid income and loving their freedom.

© Copyrights by rigid.ink trading as The Institute of 3D Printing. All Rights Reserved.

success@io3dp.com | (+44) 1937 589 052

they can 3D print, then help them scale up sales

they can 3D print, then help them scale up sales  so they can dramatically increase their income.

so they can dramatically increase their income.

and have fun doing it!

and have fun doing it!